High Speed Energy Saving Intelligent Connectivity

Consult Now

Consult Now

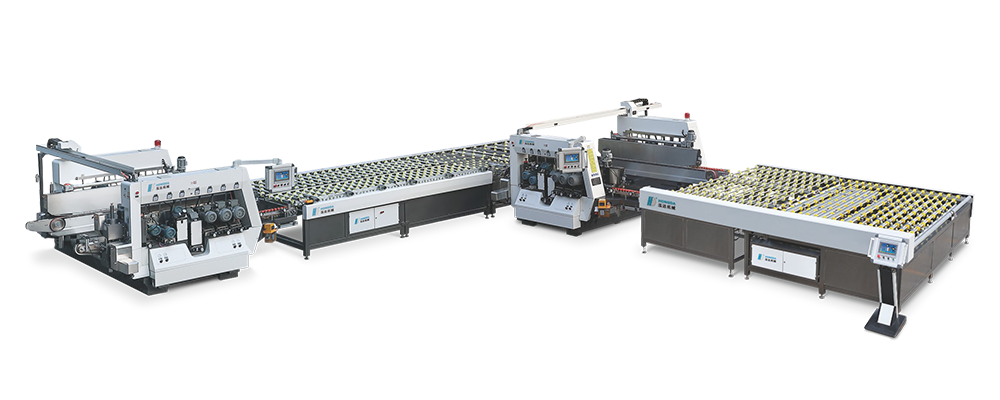

The glass high-speed intelligent double-sided edging production line is a machine specially used for processing the double straight edges of flat glass,

which is suitable for the deep processing of glass in the industries of architecture, furniture, home appliances, etc.

Intelligent configuration upgrade.

high efficient and low cost.

The width adjustment of the machine is driven by the servo motor system of Taiwan TBI high-precision ball screw. The diameter of the screw is 50 mm, which is a rare large-diameter ball screw in the glass machinery industry. It plays a decisive role in the stability of high-speed opening and closing.

The main drive uses two sets of servo motors to realize synchronous operation, and the reducer uses a hard gear reducer, which has high transmission efficiency, high speed and large load force.

The width adjustment of the machine is driven by the servo motor system of Taiwan TBI high-precision ball screw. The diameter of the screw is 50 mm, which is the largest diameter ball screw in the glass machinery industry. It plays a decisive role in the stability of high-speed opening and closing. Its advantages are fast operation speed, high accuracy, and the maximum speed of size change can reach 15 m/min. It can cooperate with intelligent equipment such as detecting table,loading and unloading table.

The key parts of Hongda manufacturing machinery grinding head cooperate with domestic CNC machine tool company to design the grinding head spindle assembly suitable for our spindle standard. We use high-precision contact balls to match bearings. The motor is a Siemens energy-saving motor with a belt shifting speed of 4500 r/min.

The lower chamfer design will install the Siemens motor on the top instead of the bottom, which can avoid the problem of motor damage caused by water ingress.

The special grinding head motor is used for the upper chamfer, and the motor speed is increased to 4000 r/min by using frequency conversion speed regulation, which is easy to maintain. At the same time, it also uses a positioning system for automatic position adjustment.

The coarse grinding head assembly of Siemens motor has a rotational speed of 4500 r/min, which has a faster grinding speed and better processing quality.

The main shaft adopts waterproof design with core technology. During high-speed operation, internal pressure will be generated inside the main shaft, and the water vapor will be discharged by itself, which ensures the stability of grinding and avoids the problem of water inflow into the main shaft.

When the direct-connected grinding head model is selected, the grinding head cooperates with frequency conversion speed regulation, and the motor speed is also 4500 rpm, so that the equipment can enter the dormant state when there is no glass entering, and the machine can resume the processing state when there is glass entering. Realize the function of energy saving.

| Automatic detecting table | Double edger | Transfer table | |

| Glass thickness | 3~28 mm | 3~28 mm | 3~28 mm |

| Processing size | 350~3500 mm | 350~3500 mm | 350~3500 mm |

| Processing speed | 1~60 m/min | 1~25 m/min | 1~30 m/min |

| Width adjustment speed | -- | 1~15 m/min | -- |

| Grinding amount | -- |

Chamfer width: 1~3 mm Basic edge grinding amount: 1~6 mm |

-- |

| Machining precision | ±0.2 mm |

chamfer width error ≤0.2 mm/m Parallelism error ≤0.2 mm/m Diagonal error ≤0.5 mm/m |

-- |

| Air pressure | 0.6~0.8 Mpa | 0.6~0.8 Mpa | 0.6~0.8 Mpa |

| Power | 3 KW | 58 KW | 5 KW |

| Working height | 900±30 mm | 900±30 mm | 900±30 mm |

Copyright ©2022 Guangdong Hongda Intelligent Technology Co., Ltd.

All rights reserved

Design by:ceall.net.cn